|

| February 28, 2017 | Volume 13 Issue 08 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Advanced combat engine aims to drive the Army's energy-efficient future

By Jerome Aliotta, TARDEC

For the U.S. Army, owner and operator of the world's largest fleet of ground vehicles, the pursuit of energy-efficiency programs that strengthen the military while meeting environmental challenges is highly important.

Outside of reducing reliance on fossil fuels, energy efficiency reduces the risk of insurgent attacks on Soldiers during refueling convoys, as a mere 1 percent increase in fuel efficiency means 6,444 fewer Soldier trips in convoys.

The challenge in reducing vehicle fuel consumption is that few solutions exist that do not involve expensive retrofitting. Fuel-reducing technologies, such as lightweighting or improved aerodynamics, are not always viable options, because they could compromise the lethality or the safety of Soldiers occupying the vehicles. To support Army goals, the U.S. Army Tank Automotive Research, Development and Engineering Center (TARDEC) has been investing in energy-efficient technology for more than two decades.

Advanced combat engine

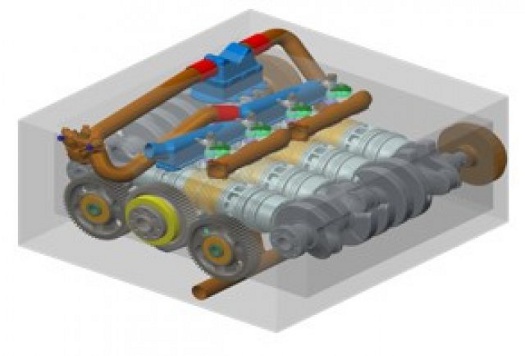

TARDEC is working to develop and demonstrate leap-ahead engine technology to meet the mobility and electrical power generation needs of future combat and tactical military vehicles in the 30-ton to 70-ton range. The prototype Advanced Combat Engine (ACE) will be a 4-cylinder, opposed-piston engine rated at 1,000 hp with 15 percent greater fuel economy and a lower thermal burden compared to commercially available engines of similar power and torque levels.

A photo illustration of an Advanced Combat Engine. [Photo Credit: Illustration by Oshkosh Defense]

"The results of the ACE engine utilizing an opposed-piston design architecture will provide significant improvement in thermodynamic efficiency over commercial-off-the-shelf engines while increasing power density, improving vehicle mobility, and reducing fuel consumption and thermal burden," says John Tasdemir, TARDEC powertrain team leader.

Commercial engine manufacturers have no real incentives to develop and produce high power-density, low-heat rejection engine concepts in the 750-hp to 1,500-hp range for military use, Tasdemir says. This is primarily due to projected low-production volumes and lack of technology insertion into their high-volume, emission-compliant engine product lines.

"The ACE project will advance the state of the art in engine technology and provide the building blocks necessary for creation of a scalable engine family to meet power and mobility needs across the future combat fleet," he says.

Joint operational energy initiative

Numerous Army initiatives seek improvements for operational energy, including the Joint Operational Energy Initiative (JOEI) sponsored by TARDEC and Program Executive Office Combat Support and Combat Service Support.

"The objective of JOEI is to develop, demonstrate, and document a modeling and simulation toolset and methodology to analyze operational energy using an integrated, system-of-systems engineering approach that enables comprehensive energy decision-making throughout the materiel development process," says Brian Ernst, TARDEC operational energy lead.

JOEI models energy consumption and generation across the battlefield area of operations. The program uses a modeling and simulation tool developed by the Department of Energy's Sandia National Laboratories called System-of-Systems Analysis Toolset (SoSAT). Using SoSAT, TARDEC developed a capability to assess impacts of technologies in a multilevel virtual scenario.

"The JOEI team goal is to develop a library of scenarios and models made up of maneuver forces, logistics support, and contingency bases, and to assess second- and third-order impacts to energy efficiency, operational effectiveness, operational adaptability, and Soldier impacts," says Rachel Agusti, TARDEC lead system engineer.

In Fiscal Year 2016, the JOEI team acquired the Fully Burdened Cost Tool (FBCT), a new analysis tool to estimate the fully burdened costs and benefits of energy and water in an operational scenario.

"With the addition of the FBCT, the JOEI team can provide quantitative evidence to evaluate materiel and non-materiel solutions, inform trade studies, conduct cost-benefit analysis, inform current and future doctrine, and inform science, technology, and current operations," Agusti says.

Tactical vehicle electrification kit

During the next year, TARDEC engineers will be working on improving fuel economy for the current tactical ground vehicle fleet. An affordable, truck-auxiliary system electrification kit will integrate on one or more existing tactical wheeled vehicle platforms. The goal is to significantly improve vehicle operational energy, range, and future electrical warfighting system growth potential.

"Our Tactical Vehicle Electrification Kit (TVEK) program has the potential to create a 15 to 25 percent reduction in fuel usage, improve vehicle mobility performance, enhance silent watch capability, provide a shore-power connection for export power capability, and possess the future electrical capability to support large electrical loads," says Phat Truong, TARDEC project lead.

A Heavy Expanded Mobility Tactical Truck A4, one of the vehicles TARDEC researchers plan to use to demonstrate the Tactical Vehicle Electrification Kit, drives over rough terrain. [Photo Credit: Photo courtesy Oshkosh Defense]

TARDEC engineers plan to demonstrate the kit on an Oshkosh Defense-built Army Heavy Expanded Mobility Tactical Truck and the Marines' Logistics Vehicle System Replacement. Components may include: an integrated starter generator (ISG), ISG controller, LI-ion 6T batteries, electrified steering, electrified HVAC, electrified engine cooling, electrified pumps, electrified air brake compressors, solid-state low-voltage supply (DC/DC converter), and a shore-power connection.

"The intent of the program is to develop capabilities for the warfighters, while the electrification kit must also be lightweight, robust, compact, and affordable," says Dean McGrew, TARDEC advanced propulsion team leader.

The TVEK project will focus on improving the current heavy tactical vehicle fleet's effectiveness and efficiency through intelligent start-stop strategy, auxiliary system electrification, and smart system controls, Truong says.

TVEK will demonstrate 15 to 25 percent fuel use reduction by the end of FY19. The project will also show capability to support future electrical needs for jamming, communications, e-weapons, and e-armor.

Single common powertrain lubricant

Replacing standard lubricants with alternative lubricants that reduce fuel consumption is one practical and relatively inexpensive way to improve fleet fuel efficiency. In order to reduce the fuel consumption of its vehicle fleet and lessen its maintenance burden, TARDEC's Fuels and Lubricants Technology team developed a new full-synthetic, all-season, fuel-efficient, heavy-duty engine oil called the Single Common Powertrain Lubricant (SCPL).

"The initial feasibility was established through successful engine dynamometer testing of MIL-PRF-46167 arctic engine oil under high-temperature desert-like conditions in three high-density military engines," says Allen Comfort, TARDEC engineer.

SCPL candidates underwent field evaluations at three separate geographic locations that represent hot, moderate, and arctic climatic conditions: Fort Bliss, TX; Fort Benning, GA; and Fort Wainwright, AK. Various tactical and combat vehicles were involved in the evaluation, which included engines from several original equipment manufacturers.

Fuel-efficient gear oil

TARDEC is also developing a new axle differential gear oil called the Fuel Efficient Gear Oil (FEGO). The project consolidates the current three grades of gear oil (80W-90, 75W-90, and 85W-140) into a single oil. FEGO will be an all-season gear oil capable of doubling oil drain intervals and improving fuel efficiency.

TARDEC's axle efficiency test stand is used in the development of Fuel Efficient Gear Oil. [Photo Credit: U.S. Army]

FEGO, which is expected to be available in the field by late 2020, will be compatible with limited-slip differential systems. These differentials are used in the Stryker Combat Vehicles, for example.

"Unlike conventional open differentials, limited-slip differentials ensure vehicles can move even if one side of the vehicle is on a low-friction surface such as ice," says Joshua Peterson, TARDEC deputy associate director. "Limited-slip differentials often employ a clutch system that requires special friction modifiers to ensure the clutch plates operate smoothly during normal turning maneuvers without causing destructive vibration or shudder."

New requirements for the FEGO, including better fuel efficiency, longer drain intervals, and limited-slip capability will be integrated into the commercial gear oil standard, Peterson says.

"Full vehicle testing showed that the combined use of SCPL in the engine and transmission and FEGO in the differentials resulted in a 6.1 percent and 7.8 percent fuel consumption improvement, respectively, over baseline lubricants, in a highway and a stop-and-go cycle," Peterson says. "Such results, applied over a large variety of military combat and tactical equipment, represent significant fuel savings and reduction in logistical burden."

Published February 2017

Rate this article

View our terms of use and privacy policy